Ziasiot® Sensor is a professional pressure transducer exporter and manufacturer that specializes in the design, manufacture and supply of kinds of high-quality pressure transmitters and pressure transducers, level sensors and temperature sensors, pressure gagues, indiactors and controllers and switches, suitable for different applications.

Advantages of ziasiot melt pressure transmitter and melt pressure transducer

1- Autozero /Magnetic zero, super anti-interference, one-click clearing, short- circuit clearing, and magnetic clearing, easy to debug on site.

2- Digital-analog integrated circuit design.

3- Intrinsically Safe, Precision, Stable and Reliable. Smart, Safety and User-

friendly

4- Dynisco & Gefran Melt Pressure Transmitter Interchangable,Mercury free & AFT technology and alloy filling, non-toxic and Eco-friendly, Cost-effective and Easy to Use.

5- Multiple parameters can be customize, Kinds of high temperature, explosion proof, capillary Exposed, Relay output, digital LCD display, Burst Plugs types for your choices, Imported stainless steel material, high accuracy level.

6- CE, RoHS, SIL2, PL ”c”; certified.

7- Rigid/Flexible Stem with/out thermocouple sensor structure optional, flexible conduit and special diaphragm isolation;

Discover Ziasiot Melt Pressure Sensors Now

Industry Challenges for High Temperature Melt Pressure

Sensors

1. High-Temperature Media Damage

In 400℃+ extreme environments, conventional melt pressure

sensors suffer from:

✔ Material Degradation – Sensor components warp or corrode under

prolonged heat exposure

✔ Data Drift – Inaccurate readings compromise product quality

✔ Shortened Lifespan – Frequent replacements increase downtime

2. Insufficient Safety Redundancy Traditional extrusion pressure transducers fail critically because they:

✖ Lack real-time overload detection

✖ Have no emergency shutdown mechanism

✖ Rely solely on software alarms (delayed response)

3. Non-Compliance with Safety Standards

Over 60% of conventional sensors can’t meet:

⚠ SIL2 Functional Safety (IEC 61508)

⚠ PLc Mechanical Safety (ISO 13849)

⚠ ATEX Explosion-Proof (for chemical environments)

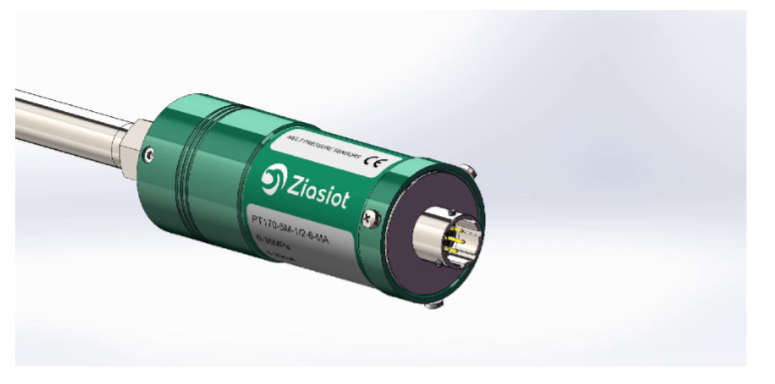

Safety Relay Type High-Temperature Melt Pressure Sensors | PT190/192/193 Series

The PT190/PT192/PT193 melt pressure sensor (also called melt pressure transducer or melt pressure transmitter) is a high-precision pressure measurement device designed for high temperature applications up to 400°C.

Engineered with TI-series high-performance digital chips and compliant with SIL2 & PL’c safety standards for plastics, rubber, and chemical processing industries, this melt pressure sensor ensures reliable and safe pressure monitoring in harsh environments.

Key Features:

✔ High-Temperature Resistance – Measures pressure in liquids, gases, or pastes at temperatures up to 400°C.

✔ Safety Relay Output – Relay-based control limits enable equipment protection by triggering safety measures when pressure exceeds set thresholds.

✔ SIL2 & PL’c Compliant – Circuit design adheres to functional safety standards, ensuring fail-safe operation.

✔ Integrated Electronics – Combines a pressure sensor + signal

conditioning module for stable, buffered output.

✔ Versatile Applications – Ideal for plastics, extrusion, chemical processing, and other high-temperature industrial environments.

Solving High-Temperature Pressure Control Challenges

Our safety relay-type melt pressure sensors address the three major challenges in rubber/plastic processing—precision, safety, and durability.

Leveraging innovative technology, they deliver accurate pressure control, ensuring production safety and consistent product quality.

Dual Safety Barrier Design

✔ TI High-Performance Digital Chip – Enables real-time fault

diagnostics and fail-safe control.

✔ Relay-Based Hard Protection – Hardware-level range limiting for active

risk prevention.

✔ SIL2 & PL’c Certified – Compliant with functional safety standards for

reliable operation.

Result: A dual-layer safety shield that protects equipment before failures

occur.

Precision Performance in Extreme Conditions

✔ Special Alloy Diaphragm – Withstands long-term molten material impact at 400°C.

✔ Advanced Thermal Compensation – Maintains ±0.3% FS accuracy across the full range.

✔ 3x Longer Lifespan – Engineered for durability in harsh industrial environments.

Result: Reliable, high-precision measurements—even under extreme heat and pressure.

Case Study: Overload Protection for Extruders/Injection Molding Machines

Instant Overload Response

✔ 0.1s Emergency Shutdown – When screw pressure surges, our safety

relay-type melt pressure sensor triggers an instant relay cutoff,

preventing screw fractures and mold damage.

✔ Cost Savings – Avoids single-incident losses exceeding ¥100,000 in

equipment damage and downtime.

Enhanced Equipment & Personnel Safety

Equipment Protection:

- Prevents screw breakage, mold explosions, and hydraulic system

failures caused by sudden pressure spikes.

Eliminates ¥100,000+ repair costs per incident.

Personnel Protection:

- Mitigates risks of flying debris, high-temperature melt leaks, and

equipment runaway.

Ensures operator safety by stopping hazards before they escalate.

How It Works:

Unlike passive alarms, our melt pressure sensor employs real-time pressure threshold monitoring + relay hard-contact intervention to actively break the risk chain at its origin—stopping threats before they occur.

Boosts Production Efficiency

✔ Real-Time Monitoring – Ensures stable machine operation.

✔ Minimized Downtime – Dramatically reduces overload-induced

stoppages.

✔ Higher Output – Maximizes productivity through uninterrupted, safer

production.

Contact Us for a Free Consultation

Related Post

Credit: www.Newshub360.net